Filling MicroClime Environmental Lids

Introduction

The MicroClime Environmental lid minimizes edge effects and preserves the concentrations of solutions in microplate wells. Unlike standard microplate lids, the MicroClime lid incorporates a unique, fluid-absorbing matrix. The absorbed fluid creates a vapor barrier that protects the sample from the exterior environment, especially near the edges of the microplate.

The MicroClime lid is easy to use—simply place it on or lift it off a microplate. No specialized tools are required, and it is compatible with robotic plate lidding systems. The lid can be filled with many different fluids, using either a hand-held syringe or automated bulk fillers.

When filled with anhydrous DMSO, the MicroClime lid prevents evaporation and hydration of DMSO in compound library plates during storage. It also stops evaporation of ultra-low-volume DMSO droplets in screening assays. The lid can also be filled with water to prevent evaporation in aqueous assays.

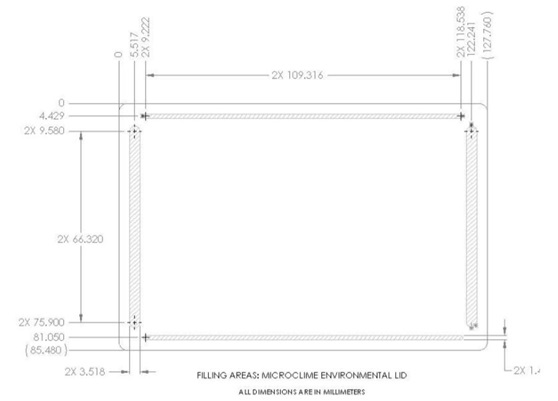

Filling Areas

In the schematic of the MicroClime lid below, the gray areas indicate the filling areas. You can dispense fluid into the short sides (left and right) with a hand-held syringe or a recommended bulk filler, or into the long sides (top and bottom) with a recommended bulk filler. Note that the filling troughs on the short sides are wider which allows easier filling.

Figure 1

Centrifuging the lids is not recommended. The fill openings are not sealed, therefore liquid will be pulled out of the absorbent matrix. Centrifuge at high speed may result in cracking the lid.

Maximum Fill Volumes

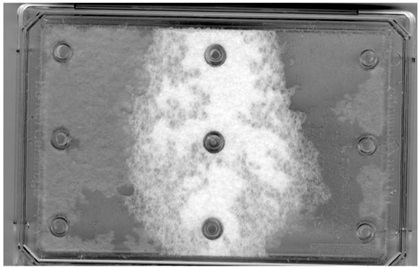

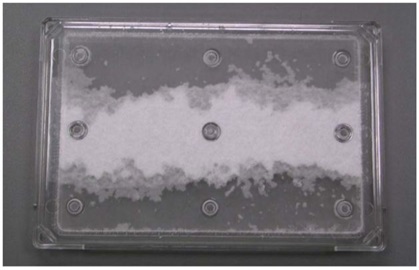

For aqueous solutions: 8 mL; for DMSO or other hygroscopic solutions: 7 mL (to allow for increase in volume as the solution absorbs water.) If the relative humidity of the lab allows hydration to lower than 70% DMSO, less fluid should be used in the lid to compensate for volume increase. When filled properly, there will be a gap in the middle of the felt where it has not been wetted, as shown in Figures 2a and 2b. The gap should be open on at least one edge of the lid to allow air to escape as the solution expands and/or hydrates. The vapor that protects the plate disperses evenly throughout the vapor barrier, so all edge wells are equally protected regardless of the gap.

Figure 2a: Image of a lid filled from short sides

Figure 2b: Image of a lid filled from long sides

With Manual Syringe

1. Use a hand-held syringe equipped with a blunt needle (16 gauge or more).

2. Dispense 3.5 mL DMSO (or 4 mL water) into the leftside trough on the short side of the MicroClime lid over a period of 15 seconds by sweeping the needle slowly up and down the left-side trough.

3. Repeat Step 2 with the right-side trough. The filled lid should resemble the image in Figure 2a.

4. If large drops are left in the troughs, a lab tissue should be used to clean off the lid.

References

Ellson, R.; Kong, B.; Mutz, M.; Miller, M.; Bramwell, A.M.; Jamieson, R.B. “Compound Preservation in Closed Loop Screening”, 11th Annual Conference of the Society for Biomolecular Screening, Sept. 2005

Ellson, R.; Kong, B.; Mutz, M.; Brown, C.; Browning, B.; Harris, D.; Qureshi, S.; Shieh, J; Wold, D. “In situ DMSO Hydration Measurements of HTS Compound Libraries” Combinatorial Chemistry & High Throughput Screening, 8(6):489-498, 2005.

Ellson, R.; Shieh, J.; “Managing Compound Library Health Through Solvent Restoration.” 8th International MipTec Conference, May 2005.