The New Avanti J-15 Centrifuge Time Saving Deceleration Profile Improves Workflow Efficiency

Content Type: Application Note

Author: Julia P Luciano-Chadee | Beckman Coulter, Inc., Indianapolis, IN 46268

Abstract

Time, temperature and speed are the basis of centrifugation. While there have been increasing advancements in the study of biologics with proteomics, protein sample purification and preparation is still lengthy and require multiple time consuming steps. As researchers strive to obtain high quality samples fast and efficiently, many laboratories struggle to find instruments that maximize instrument usage in a multi-user environment. The new Avanti J-15 series centrifuges by Beckman Coulter Inc. were designed to address customer efficiencies without compromising on sample quality. The implementation of Ultra Harmonic Technology into the Avanti J-15 series renders our centrifuge ideal for applications that require multiple runs. It saves up to 10% of instrument usage time for a single application and the time savings maximizes overall laboratory assent management.

Introduction

The use of tabletop centrifugation is ubiquitous to many lab and its use covers a wide range of applications. From the first steps of harvesting and pelleting to more refined protein concentration protocols, centrifugation is heavily used in the day-to-day operations of a scientific laboratory. Often times the centrifuge is used by more than one individual and multiple protocols are performed, which can lead to high demand of instrument availability. As traditional tabletop centrifugation primarily considers time, temperature and speed as pillars of centrifuge design, Beckman Coulter is revolutionizing the market with the newly designed Avanti J-15 series centrifuges that maximize the efficiency of acceleration and deceleration with the implementation of Ultra Harmonic Technology.

The Ultra Harmonic Technology optimizes time by implementing faster acceleration and deceleration profiles without compromising on sample quality. The time that it takes for a spinning centrifuge to apply the brakes and come to a complete stop adds up to the complete workflow time. In protocols that require significant multiple cycles, the time savings for each cycle can result in significant workflow efficiency. The experiments here were conducted to illustrate relative time efficiencies of the Avanti J-15 centrifuge versus the Beckman Allegra.

Materials and Methods

BSA (cat. A7906-10G) was purchased from Sigma-Aldrich. Amicon Utra-4 10K MWCO centrifugal filter devices was purchased from Millipore.

Avanti J-15R (P/N B99517, B99516, B99515, B99514) equipped with JS-4.750 rotor (P/N B77580), and Allegra 14R (P/N A99465) equipped with SX4750 rotor (P/N 392806) were from Beckman Coulter.

A total volume of 100 mL of BSA was prepared at 1mg/mL in 1xPBS. To verify protein concentration, the optical density measurement (OD280) of the initial solution was measured using the Beckman-Coulter DU730 UV/Vis Spectophotometer with a 10mm pathlength.

Each instrument was configured to spin at 4,000 x g for 10 minutes and a total of 10 runs with maximum acceleration and deceleration profiles. A single Amicon filter with sample was assigned to each centrifuge. In the beginning of each run, 4 mL of solution was added and mixed to the centrifugal insert, and a total of 40 mL of BSA solution was concentrated in each centrifugal device. The time for each run was recorded as set time and recorded time. Following the last centrifugation step, the OD280 of each BSA was measured using Beckman-Coulter DU730 UV/Vis Spectophotometer and recorded.

Results and Discussion

We compared the time for each run and recorded the time based on: (1) set time, 10 minutes manual instrument input; and (2) actual time as the time from start of rotor rotation to a complete rotor stop. Table 1 shows run times for the Avanti J-15R and Table 2 shows run times for the Allegra 14R. The average time for each instrument was also calculated.

| Avanti J-15 R (mm:ss) | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Average | |

| Set Time | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 |

| Actual Time | 10.49 | 10:53 | 10:55 | 10:54 | 10:55 | 10:50 | 10:54 | 10:55 | 10:56 | 10:46 | 10:52 |

| Table 1: Avanti J-15R run times | |||||||||||

| Allegra 14R (mm:ss) | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Average | |

| Set Time | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 | 10:00 |

| Actual Time | 12:03 | 12:01 | 12:02 | 12:03 | 12:03 | 12:02 | 12:01 | 12:03 | 12:02 | 12:01 | 12:02 |

| Table 2: Allegra 14R run times | |||||||||||

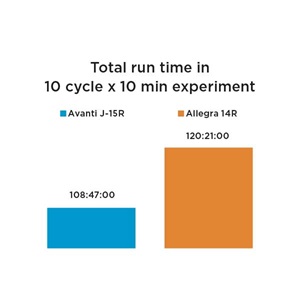

In average each run was performed 1 minute and 10 seconds faster in the Avanti J-15R instrument compared to the Allegra unit. Most importantly, over the course of a 10 cycle experiment, the cumulative effect of each run results

in significant time savings (Figure 1). Compared to the Allegra 14R, the Avanti J-15R completes a 10 cycle experiment 12 minutes faster. Overall, there is an improvement in time efficiencies over 10%.

In average each run was performed 1 minute and 10 seconds faster in the Avanti J-15R instrument compared to the Allegra unit. Most importantly, over the course of a 10 cycle experiment, the cumulative effect of each run results

in significant time savings (Figure 1). Compared to the Allegra 14R, the Avanti J-15R completes a 10 cycle experiment 12 minutes faster. Overall, there is an improvement in time efficiencies over 10%.

In addition, we recorded the initial and final of the OD280 BSA protein. The results are reported in table 3 and concentration was calculated based on BSA extinction coefficient. The initial concentration of the solution contained BSA at 0.97 mg/mL. A total of 40 mL of BSA mixture was used for each experimental run, therefore 38.9 mg of protein was concentrated. At the end of the run, 36 mg of BSA was recovered from the concentrator spun in the Avanti J-15R, and 35 mg of BSA was recovered from the Allegra 14R concentration. A rate of 90% sample recovery was consistent in both samples.

| Sample | Initial OD280 | Initial Volume | Initial BSA | Final OD280 | Final Volume | Final BSA |

| Avanti J-15R | 0.642 | 40 mL | 38.9 mg | 16.461 | 1450 μL | 36 mg |

| Actual Time | 0.642 | 40 mL | 38.9 mg | 15.034 | 1550 μL | 35 mg |

| Table 3: BSA recovery from centrifugal devices | ||||||

While performing multi-step short cycled laboratory protocols, such as protein concentration using centrifugal devices, users rely on rapid and efficient instrument usage. With the Avanti J-15 Ultra Harmonic Technology users can maximize time while performing experiments, which leads to (1) fast instrument turn over and (2) quicker follow through to the next step. The latter is important because it allows for a greater rate of sample protection, with less idle time of samples being exposed to air and temperature fluctuations. In the case of proteins, nuances in purification parameters can lead to detrimental structural effects. The results of structural changes of a protein would make the sample unusable and a loss in time and resources. The second advantage of the Ultra Harmonic Technology in workflow efficiencies is overall instrument management, as faster turn over leads to improved instrument usage and management.

Conclusion

Workflow efficiencies is of major interest in the scientific community because it addresses factors that can influence time spent in performing scientific experiments. Here, we showed that the incremental time savings achieved with each cycle in the Avanti J-15 can lead to substantial overall workflow saving. The advantages of the Ultra Harmonic Technology allows for faster deceleration time without compromising sample recovery.

The Avanti J-15 series instruments incorporates important features of acceleration and deceleration, present in refined ultracentrifugation, into tabletop centrifugation, therefore reducing the time it takes to go from zero to set speed, and vice-versa. The performance of the Avanti J-15 instrument does not compromise sample yield, and important consideration of the instrument design.

The Avanti J-15 centrifuge is a great addition to a lab that prioritizes sample recovery and time efficiency.

CENT-3122APP10.17